Specifically designed to provide strong resistance against objects that might rip through the belt, impact-resistant conveyor belts are used for carrying jagged materials in heavy-duty conditions, especially where large drop heights are involved. Impact-resistant belts operate effectively in this environment due to a special textile or metal weave, known as a breaker.

The material used for the breaker differs, depending on the application: high elongation steel mesh is used as a weft cord for increased lateral strength, while regular steel mesh can be used for increased lateral stiffness. Breaker material is also available as a fabric weave, featuring increased impact resistance for lighter working conditions, where steel is not needed.

The rubber covers are equipped to handle the impact, minimize rips and tears, resist aggressive wear and reduce gouging and cutting caused by hard, sharp materials.

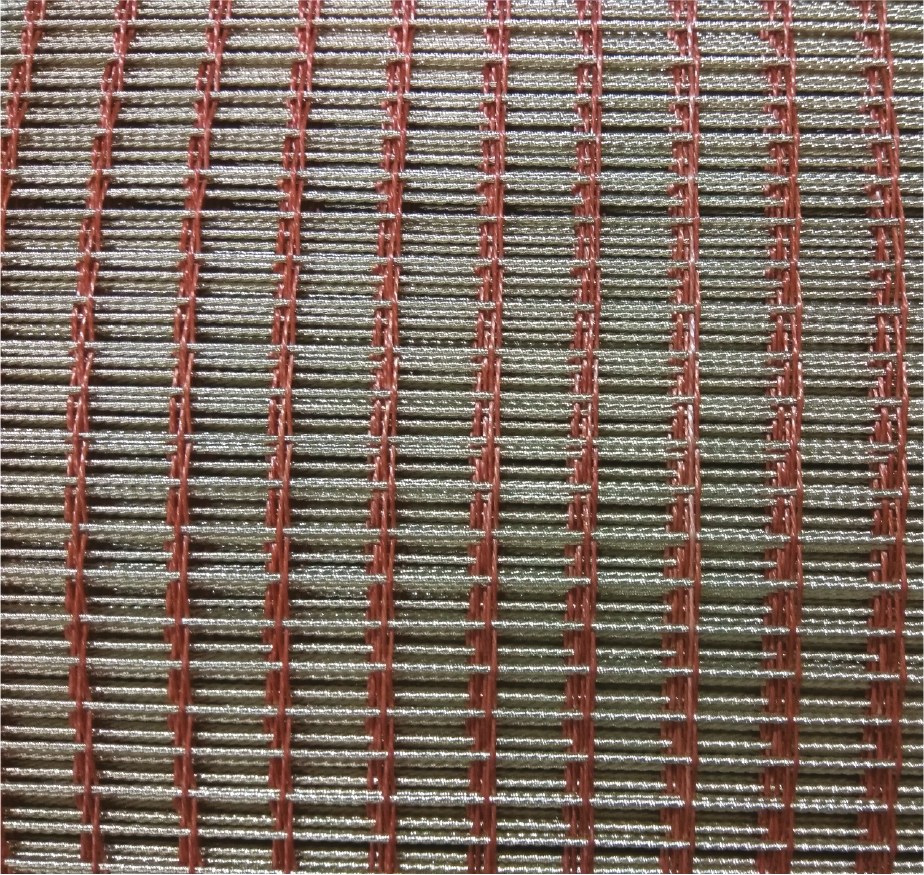

BF-HE Series Fabric

Woven with polyester cord as warp and steel cord as weft.

Provides high resistance to tearing and puncture

Provides high grooveability

Can be adapted with all cover grades.

BF-RE Series Fabric

Woven with polyester cord as warp and steel cord as weft

Provides high resistance to tearing and puncture

Provides extra transverse rigidity

Suitable to use at Elevators and Sidewall belts

Can be adapted with all cover grades.

SW conveyor belt is made of high-quality steel cord fabric, the longitudinal and transverse steel cords are fixed together with a layer as the carcass. Because of its high impact strength and trough capability, it can be used for many purposes.

Compared with fabric belts, SW belts are stronger, tear-resistant, and more suitable for high-temperature use. Compared with steel cord belts, SW belts are lighter, more energy-efficient, and have good trough capabilities.

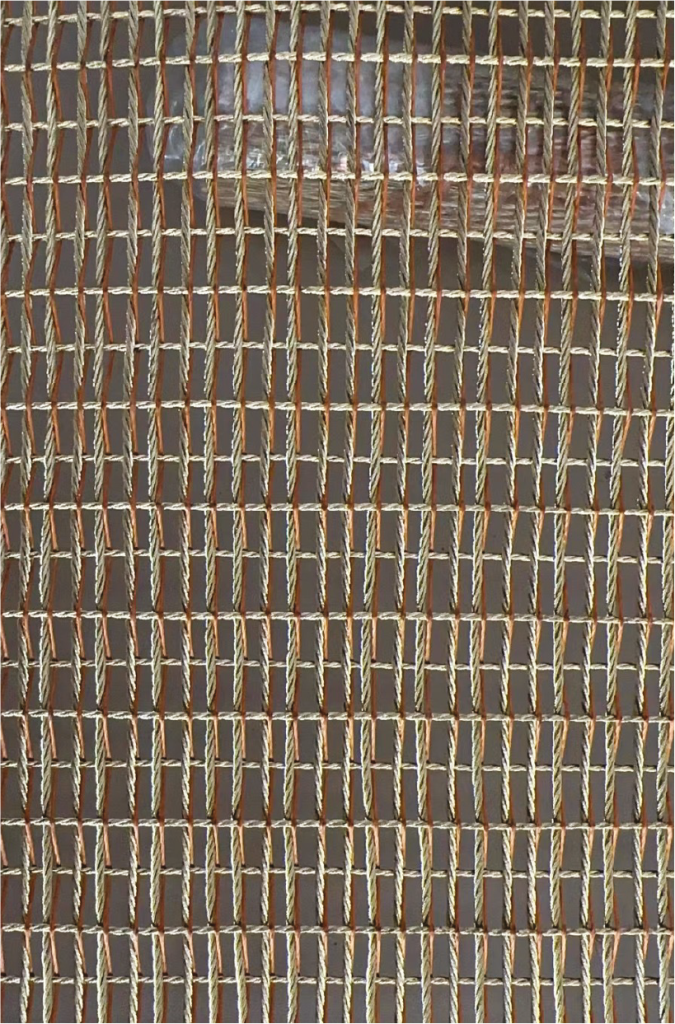

IW Series Fabric

Woven with polyester cord and steel cord as the warp, and the steel cord as the weft direction is located at the upper and lower parts of the warp cord to weave a one-layer straight warp and straight weft steel cord fabric belt core.

Optimal load bearing capacity and limited stretching

Low Elongation at Operating Load : 0.5%

Can be adapted with all cover grades.

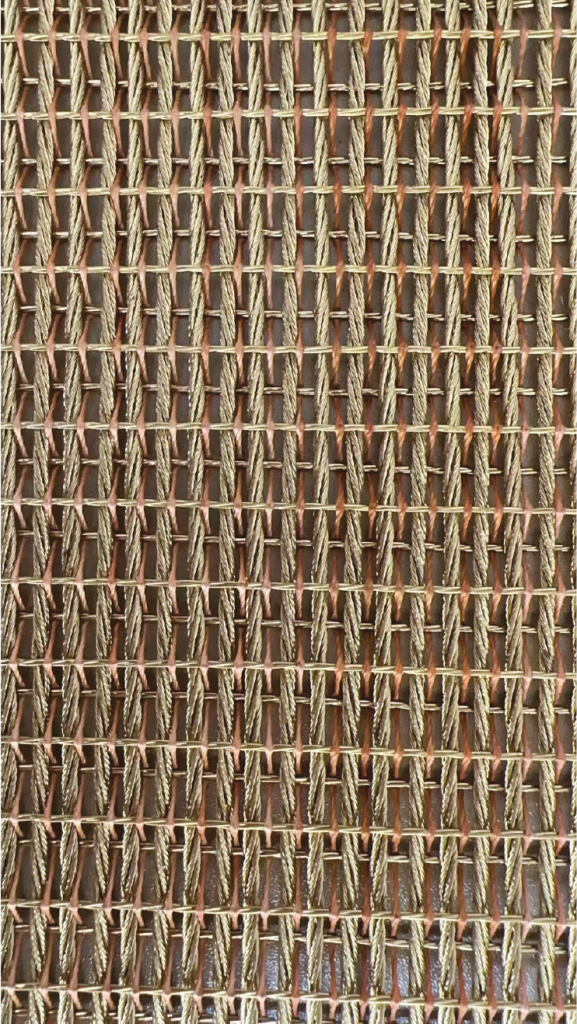

SW Series Fabric

Woven with polyester cords and steel cords as the warp, and the steel cord as the weft direction is located at the upper and lower parts of the warp cord to weave a double-layer straight warp and straight weft steel cord fabric belt core.

Increase bucket bolt holding ability

Low Elongation at Operating Load: 0.5%

Can be adapted with all cover grades.